Project

Advanced technologies for future mining.

Vision and Mission

Electrifing our future means higher demands of materials - especially copper for wires, generators, transformators, and electric appliances. Copper is contained in ores like Chacopyrite or Bornite - usually mined in open-pit mines in Chile, Peru, or the Indonesian Archipelago. Estimates show that demand will growth threefold within the next 30 years [Visual Capitalist: Copper Demand for Renewables].

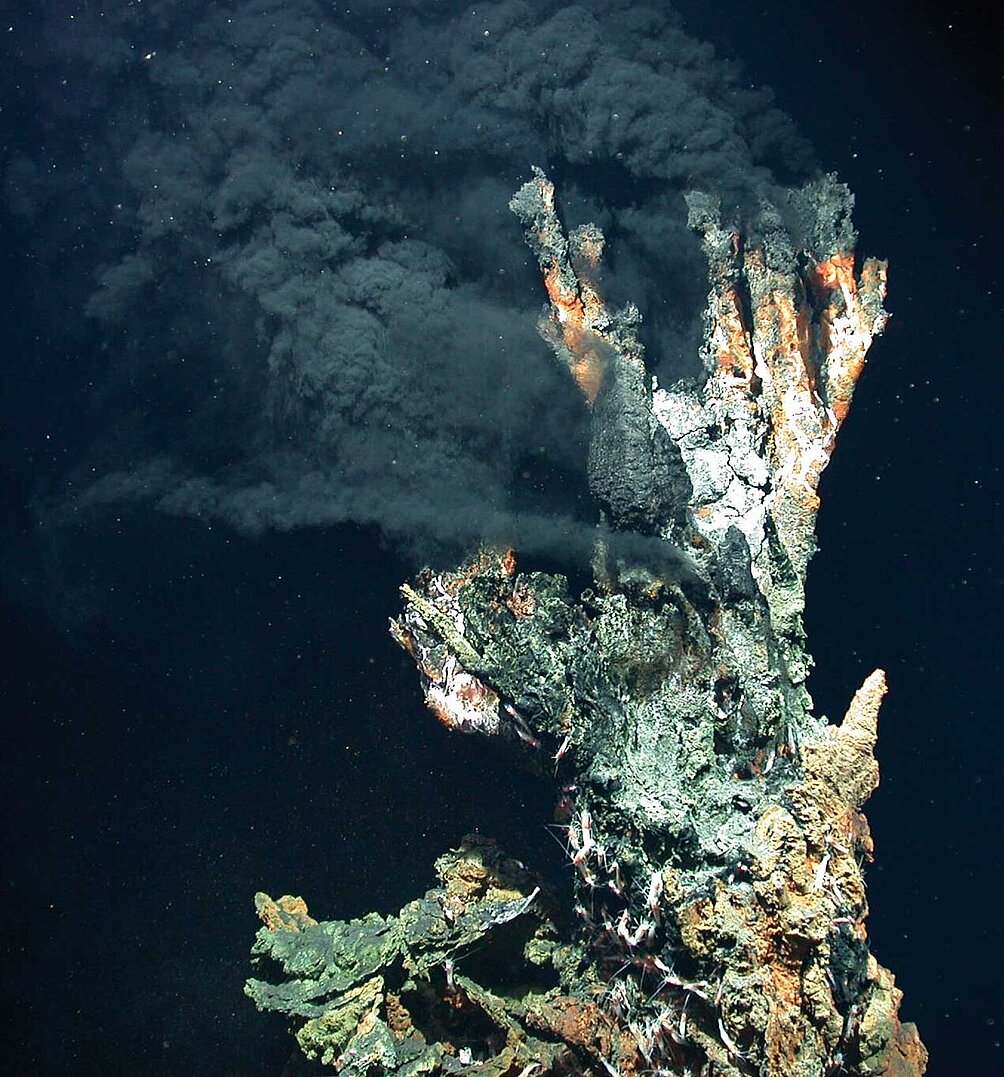

To meet that demand either production and productivity of existing mines has to be increased dramatically - with all resulting consequences. An alternative approach is to mine the ore directly at spots where they are formed: in the rift zones of the oceans. While ores in terrestrial mines usually contain 0.5 to 1.2% of copper, buried under overburden of upt to several hundred meters, ore formed by black smokers can contain up to 25% copper, and can be found literarily atop the seabed.

Utilizing these ore means a minimum of energy to mine the ore and much lower resource consumption to process it. The impact of mining can be reduced to the minimal necessary incoursion.

The decades to come will be the decades of ore mining.

A new kind of ore mining.